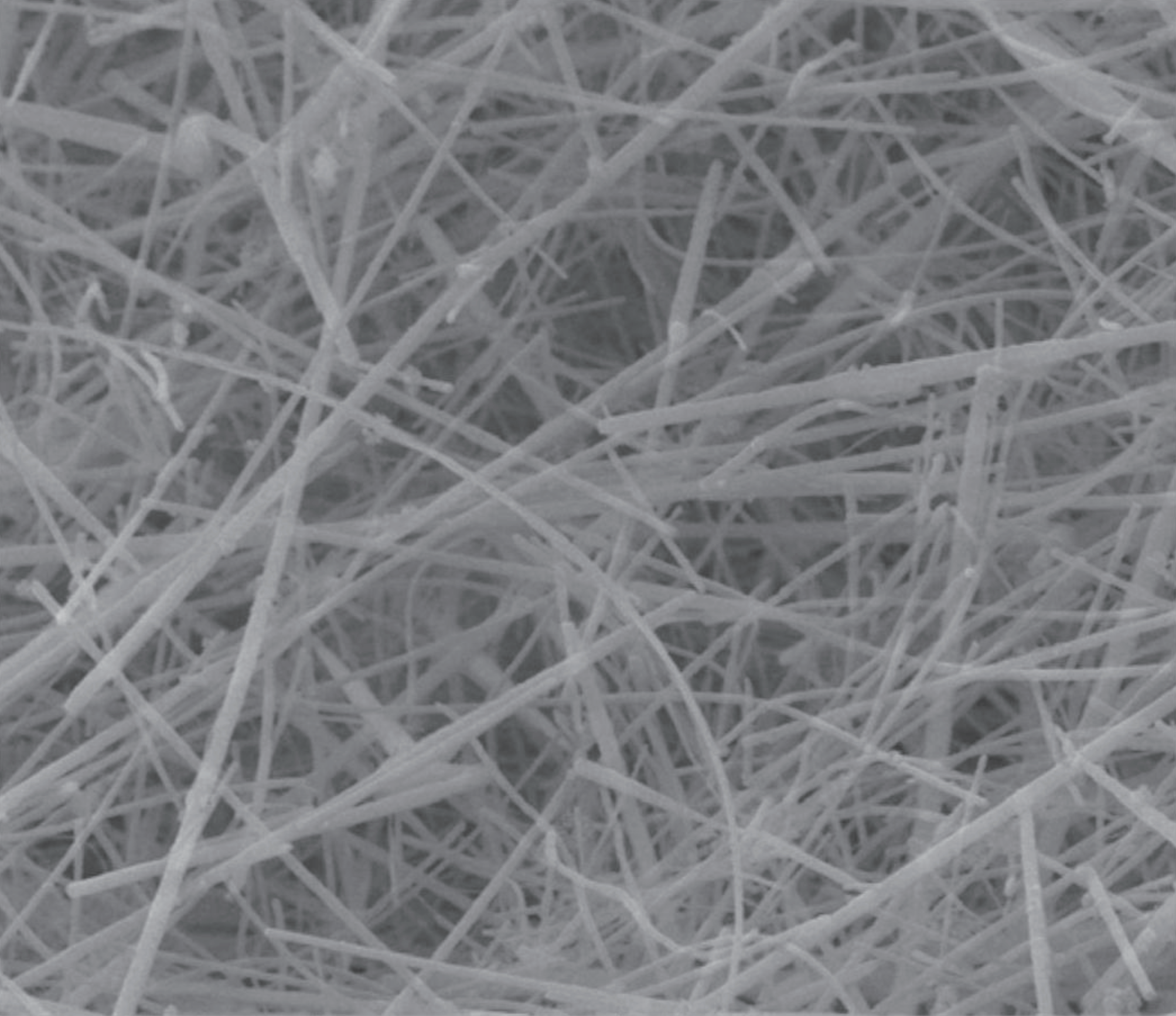

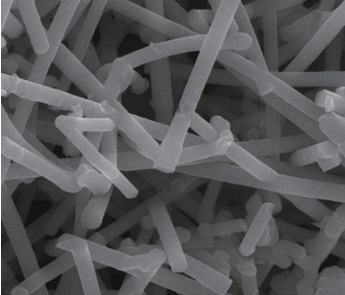

Aerogel fiber growth technology

The first template-assisted gas reaction method to directly synthesize silicon nitride nanoribbon aerogel with macroscopic three-dimensional size:Excellent high temperature stability: at 1000°C high temperature for a long time service structure without any change, no harmful products generated.

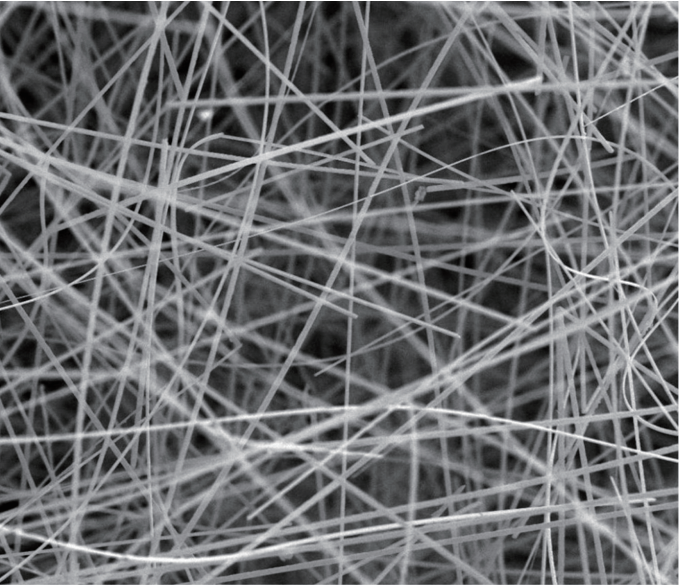

Aerogel fiber reinforcement technology

The morphology and pore size of nanowires can be easily controlled by controlling the deposition process.

Silicon carbide is deposited only on the surface of ceramic nanowires, achieving the goal of "using as little material as possible to achieve the highest possible mechanical strength".

Focus on R&D Strength

![]()

R&D personnel account for 40%

![]()

Nearly 20 patent applications a year

![]()

Basic R&D investment accounts for more than 20%

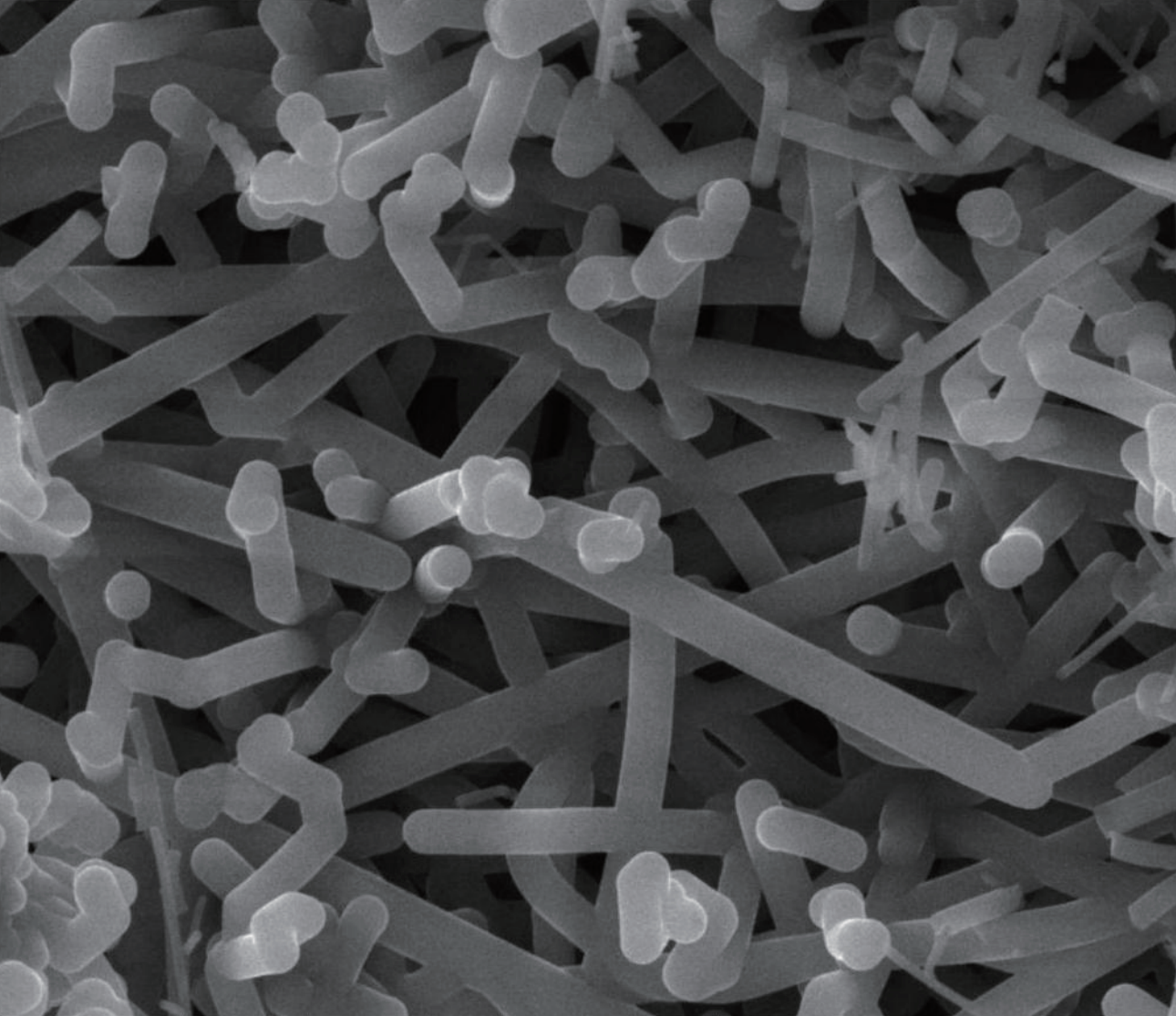

Aerogel atomizing material advantage

![]()

The world's first SiC aerogel atomization material

![]()

Three-dimensional silicon carbide nanowire aerogel

![]()

The structure has no significant change, no harmful substances produced

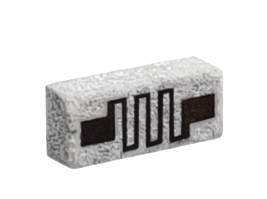

AEROCORETM™ is a new type of aerogel atomizing core, which has many excellent properties including high strength,

large porosity, adjustable and uniform pore size, fine atomization, strong oil guiding and oil locking ability, safe and pure.

It can meet the customized needs of different customers,giving the end consumers a delicate, healthy,stable atomization and taste experience.

The product can be applied to atomise differentfinished e-cigarettes such as disposable, swap-pable, cBD and so on, among which the focusis on CBD electronic smog.

AEROK™ atomiser core is a new type ofaerogel composite ceramic atomiser corewith large aperture, fast oil conduction,high strength and other excellent proper-ties,

which can meet the needs of differentcustomers for multi-functionality and lowcost, and bring the end consumer a largesmoke, highly reproducible taste experience.

The product can be applied to atomise differentfinished e-cigarettes such as disposable, swap-pable, cBD and so on, among which the focusis on CBD electronic smog.

|

lteration |

1.0 Cotton core |

2.0 Ceramic core |

3.0 Aerogelatomizing core |

|

Aperture/μm |

59-90 | 10-30 | 0-40 (tunable) |

|

Porosity% |

/ | 50-60 | 80-95 |

|

Intensity/Mpa |

/ | 2-4 | 5-10 |

|

Security |

Poor | Average | Excellent |

|

Atomization Efficiency |

Low | Average | Higjh |

|

Service Life |

Shorter | Average | Longer |

|

Leakproof Property |

Poor | Good | Excellent |

|

Temperature Control Performance |

Average | Good | Excellent |