One core can revolutionize an entire industry! Behind NVIDIA's success lies its mastery of core computing chip module technology. Zijing Future, with iteration as its mission, strives to become the "Intel" of the intelligent atomization core industry, focusing on the research and application of atomization core materials. It has successfully developed the world's first silicon nitride (Si₃N₄) nano-aerogel intelligent atomization core. This technological breakthrough directly elevates atomization core devices from traditional cotton cores (1.0) and ceramic cores (2.0) to nano-aerogel intelligent atomization cores (3.0) era! The porosity has been increased to 85%, the pores have changed from curved to straight, and the operating temperature has been significantly expanded from 100°C to 1000°C. The solidification and formation of these technical parameters have directly opened up three major application scenarios: electronic atomization, medical atomization, and space disinfection. Particularly in the application of consumer electronics, throat disease treatment, and military fields, it has attracted the high attention of industry giants and investors in the atomization industry! New material entrepreneurship is a journey without shortcuts. From research to application, it requires decades of continuous investment and breakthroughs. This gamble of technology and time has deterred many potential entrants. Even a veteran in new materials like Wu Haiming still needs to be mentally prepared before embarking on this new journey. "The internet industry had opportunities for wild growth, but there are no shortcuts in the basic science of new materials. We can only proceed step by step," he said.

New materials expert, China rare earth new materials industry researcher, domestic well-known equity investor Wu Haiming

With enthusiasm for new materials and forward-looking thinking, Wu Haiming has crossed the boundary into the electronic atomization industry track, taking silicon nitride nano aerogel functional materials as the technical direction of new material application, and is committed to leveraging the industrial application technology of new aerogel materials to change the industry. Today, Bauhinia Future Technology, as a cutting-edge scientific and technological innovation platform, relying on high-end material industry technology and human resources, has made key technological breakthroughs in the application of silicon nitride nano new materials in the field of atomization. This technology iteration has injected core competitiveness into the enterprise, and promoted scientific research achievements to a wider range of application scenarios and industries. Why does the new material Track drive the development of enterprises with innovation? What is the right way to start a new material business? In the exploration of these issues, Bauhinia future technology is undoubtedly a sample worth studying.

New material veteran cross-border layout "long-term track"

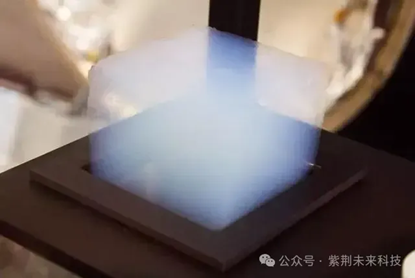

Aerogel is known as "solid smoke", is the world's lowest known density of artificial solid materials, excellent heat insulation, insulation properties, so that it in basic physics research and industrial applications have shown unprecedented prospects.

Aerogel solid

A few years ago, Wu Haiming was keenly aware that the aerogel material with such excellent performance was used as a fireproof insulation material between the batteries of new energy vehicles at that time, and many application scenarios have not been developed. In the field of electronic atomization, it has always been a direction of researchers' efforts to promote the iterative upgrading of consumer electronic products such as electronic cigarettes through material changes. Wu Haiming first noticed the broad market prospects of atomization technology in the consumer electronics track, according to the 2022 e-cigarette industry Export Blue Book report, the global e-cigarette market size will exceed 108 billion US dollars in 2022. Electronic cigarettes are mainly composed of three parts: smoke bomb, smoke rod and atomizer, of which the crucial structure is the atomizer, and its core component atomizer core plays a very important role in transformation. The atomization core has mainly experienced material changes from the earliest glass fiber core to the resistance silk and cotton core to the ceramic atomization core. At present, the mainstream heating atomization core uses porous ceramic material, but it has problems such as large aperture, low porosity, fast thermal conductivity, and low thermal energy utilization rate, which affects the performance and user experience of the atomization core, and also restricts the development and progress of heating atomization products. The intuition of senior "material people" made Wu Haiming realize that the iteration of downstream demand is making atomizing core materials face a trend replacement. At the same time, with the iterative progress of atomization technology, the application boundary of atomization is also expanding. In the near future, atomization technology can empower medical, beauty, military to industrial and agricultural industries, and promote technological innovation in more industries, which coincides with Wu Haiming's original intention to promote industry change with material innovation. "We believe that through the efforts of experts and scientific research institutions in the field of materials science, we have the ability to break through and improve the materials used in current electronic atomizers, achieve cost reduction and efficiency, and inject scientific and technological momentum into the development of the industry." Wu Haiming said. The judgment of this trend has led Wu Haiming to dive into the entrepreneurship of new materials. Bauhinia Future Company was founded by Tsinghua University, Xi 'an Jiaotong University, Institute of Mechanics of the Chinese Academy of Sciences and other scientific research teams and technology research and development results, spearheaded the launch of Bauhinia Future Technology, the core strategy is to continue to develop and invest in new material technology. At the same time, the company launched the aerogel intelligent atomization chip project, which is committed to in-depth study of new material frontier technology and atomization technology, and apply new materials and new technologies to various atomization scenarios.

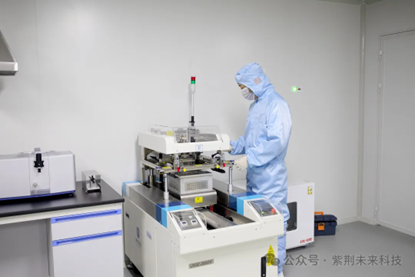

Comply with the national demand, R & D stand to build long-term core competitiveness. In August 2023, the National Ministry of Industry and Information Technology selected high-performance aerogel insulation materials into the "Cutting-edge materials industrialization key development guidance catalog (the first batch)" for details, see the "Ministry of Industry and Information Technology joint original letter (2023) No. 213" "On the publication of cutting-edge materials industrialization key development Guidance catalog (the first batch) notice. In recent years, the State Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Science and Technology of the aerogel industry development policy is frequently favorable, the industry development boom is getting higher and higher, the entire industry will ushered in a golden period! "Aerogel industry in the intelligent atomization, flame retardant insulation, green building materials three tracks in the development of at least one trillion market output value! Wu Haiming confidently said, especially in the intelligent atomization industry has hundreds of billions of scale to take off again, coupled with aerogel in the new energy battery pack flame retardant heat insulation market has been highly recognized by mainstream manufacturers, the mass production of green building materials is also about to spread out a large area of spectrum, this industry can give birth to a number of unicorns! In the development and testing process of the first silicon nitride nanoaerogel intelligent atomization core, "behind every 10% increase in porosity, it is necessary to go through repeated temperature and strength indicators such as detection, so as to constantly debug the formula and adjust the program, which is an extremely tedious and time-consuming process." Recalling the team's difficult journey in the development process, Wu Haiming is very emotional. When entrepreneurs and scientists meet, in this battle of science and technology, they support each other and work hard together. Continuous investment in research and development, as well as sufficient financial security, finally make the seeds of scientific research bear fruitful fruit.

Laboratory research and development testing

This year, the R&D team successfully developed a new technology route for silicon-based ceramic fiber aerogel. This innovative technology not only solves the problems of brittleness and "dropping powder" of aerogel, but also significantly increases its use temperature to 1500 ° C, far beyond the 650 ° C upper limit of conventional aerogel. The product range includes silicon carbide, silicon nitride and silicon oxide fiber aerogel. By using silicon nitride nanolibbon aerogel and its preparation technology, the porosity of SiC aerogel atomizing core exceeds 80%, which is 30% higher than the current level, and the strength of porous ceramics with high porosity is maintained at the leading level in China.

The world's first SiC aerogel intelligent atomization core

Thanks to their unique material properties, these aerogel products can also be made into felt, plate and various complex shapes, further opening the imagination of new materials and unlocking more possible application scenarios.

SiC aerogel felt (left) and SiC aerogel block (right) Wu Haiming compares aerogel preparation technology to the "chassis technology" of a car. He explained that only the "chassis" is stable enough to carry equipment and achieve various functions on this basis, which is the "vehicle technology" part. In the working principle of e-cigarette, after the user inhales, the air flow sensor senses the air flow and activates the atomizer to atomize the soot into steam. The manufacturing process from atomizing core material to atomizing core device involves five key links: gas, fog, oil, temperature and electricity. Because of the different needs of different manufacturers and users, a flexible configuration method is needed, just like "vehicle technology", which needs to meet individual needs. This is a key step to determine whether the original scientific research results can be successfully industrialized. After years of practical exploration and summary and cross-industry strategic planning ability, Wu Haiming has explored a new paradigm of industrial transformation of scientific research achievements - to carry out product research and development and technical research by combining independent research and development with external cooperation. "A person's energy, power and time are limited, and a company is the same. We need to explore the combination of scientific and technological forces." Wu Haiming said. In view of the five key pain points of intelligent atomization components, Bauhinia Future Technology adopts the strategy of open collaborative innovation, and united the upstream and downstream enterprises of the industrial chain, institutional associations, scientific research institutes and other forces to build a platform for resource sharing and cooperative innovation, and work together to overcome technical difficulties. In the field of air flow technology, the Bauhinia team has carried out in-depth cooperation with the School of Materials of Tsinghua University, the School of Materials of Xi 'an Jiaotong University and the Institute of Mechanics of the Chinese Academy of Sciences to jointly solve the problem of air flow control. In terms of atomization and temperature regulation, the Institute of Engineering Thermophysics of the Chinese Academy of Sciences provides strong technical support.

The first aerogel atomizing core rolling off the assembly line

Bauhinia Future Technology continues to invest in technology research and development, platform construction and other aspects, and constantly helps itself to enhance its long-term core competitiveness, so that it can seize opportunities and drive to the blue ocean of the application market.

Steady and long-term enterprise growth interpretation of long-term doctrine

The road to industrialization of new material technology is difficult, not only because of the length of the track cycle, but also because of the rapid change of trends. New materials play a key role in cutting-edge scientific and technological fields such as new energy vehicles, rail transit, aerospace, and medical devices. In recent years, the rapid development of high-tech and industry in China has constantly put forward new requirements for new materials, which has reversely promoted the continuous innovation and iteration of relevant enterprises. Bauhinia Future Technology takes "iteration" as its mission, and in the interview with Wu Haiming, the word "iteration" is also frequently mentioned by him.